Kanyapur, Asansol, West Bengal

- GST NO. : 19AAJFA1239L1ZA

+91 9831692115 Call / WhatsApp |

View Mobile Number Call Us |

ajmani.associates@rediffmail.com Drop us a line |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

We have parted our infrastructure into several units and one of them is storehouse. We update it on regular basis so as to meet stated industry standards. The assistance of our quality auditors helps us in acquiring quality-approved raw materials from the certified vendors. Thus, we ensure that our products are of unmatched quality.

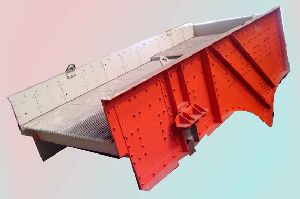

Function

- Ajmani the manufactures impact crushers crush the feed by the reciprocal effect of shock and impact.

- Rotating baffle plates pick up the material and fling it against the armoured impact vibrators.

- During the impact the material is split at the natural cleavage faces to become cubical final products Without cracks.

Design

- Welded ,rugged casing

- Screwed lining with high-carbon steel plates

- Hydraulically swiveling upper part

- Detachable connection of disk-type rotor and shaft

- Replaceable baffle plates,quadruple exploitation

- Dust proof self-aligning roller bearings of the rotor shaft

- Pendulum suspension of the impact vibrators

- Infinitely variable mechanical or hydraulic crushing edge adjustment

Pros

- Rugged structural shape

- Easy maintenance

- High degree of crushing

- Insensitive to foreign substance

Application

- Cement and limestone plants

- Coal, ore and potash mining

- Building, glass and chemical industries

- Steel works

To enable our experienced engineering staff to recommend the installation best suited to specific applications,answers to as many of the following questions as possible will result in a prompt and accurate solution to your screening requirements

- Material to be crushed

- Maximum feed dimension

- Approximate feed size analysis

- Moisture content

- Stickiness

- Bulk Density

- Product sizes required

- Friability

- Abrasive Characteristics

- Do you intend close circuit operation

- Capacity desired in tons per hour

Looking for "Impact Crusher" ?

Explore More Products