Kanyapur, Asansol, West Bengal

- GST NO. : 19AAJFA1239L1ZA

+91 9831692115 Call / WhatsApp |

View Mobile Number Call Us |

ajmani.associates@rediffmail.com Drop us a line |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

We have a good rapport with the prominent e-commerce merchants who provide us a secure payment gateway. With this, we guarantee instant and hassle free transactions. Our complete range of product is wrapped in strong, nontoxic, and superior-grade packs that protect the contents inside from damage, moisture, logistic movement, etc. Furthermore, the packaging has product details printed on it.

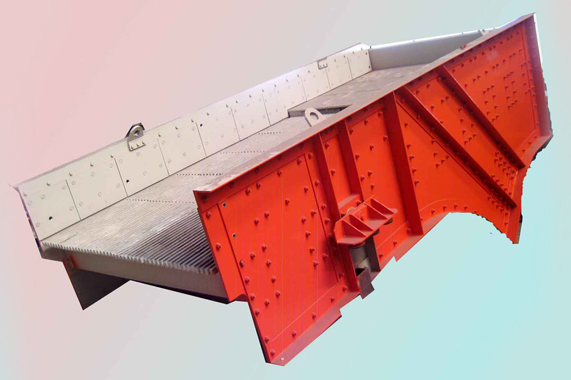

- Grizzly screens/Feeder are usually employed to extract coarse material from storage hoppers and convey it to downstream crushers. They are used for screening smaller grain size in the feed material which does not require crushing. Grizzly screens/Feeder are specially designed for such application.

- The Grizzly Screens/Feeder are Liner Motion & of bolted structure with a highly rigid design. The screen body consists of the two side plates with bolted transverse supports and screen mounts. The screen box is based on an open design.

- The Grizzly screen is supported above the substructure by means of helical coil compression springs. The screen installation angle can be varied to suit the application.

- The drive is through direct force exciter and Cardon shaft. The angle of throw is determined by the construction and application but usually 35 to 60 degree. The counterweights can be adjusted in stages from 50 to 100%. for variation of amplitude.

- There are several options for lubrication, oil or grease, which can be used without modification. Selected bearing seals ensure a long service life.

Applications:

- Coal, Coke, Pet Coke, Lignite, Limestone, Dolomite

- Minerals, Ores, Pellets, Sinter

- Sand and Gravel, building materials

For Sizing and selection by our experienced engineering staff & to recommend the installation best suited to specific applications, answers to as many of the following questions as possible will result in a prompt and accurate solution to your screening requirements.

- Material to be screened

- Maximum feed dimension

- Approximate feed size analysis

- Moisture content

- Stickiness

- Bulk Density

- Separation sizes required

- Friability

- Abrasive characteristics

- Do you intend close circuit operation?

- Capacity desired in tons per hour

Looking for "Vibrating Grizzly Screen" ?

Explore More Products