Kanyapur, Asansol, West Bengal

- GST NO. : 19AAJFA1239L1ZA

+91 9831692115 Call / WhatsApp |

View Mobile Number Call Us |

ajmani.associates@rediffmail.com Drop us a line |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

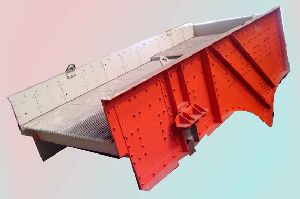

Working in assistance with a brilliant inventory management system and capacious storehouse has enabled us to entertain urgent and massive requirements of the customers. Being a prominent name in this area of operations, we, as a Supplier, bring forth qualitative array of Impact Hammer Crusher.

Function

- Ajmani impact hammer crushers crush the material by the reciprocal effect of impact and friction between the hammer heads and dht hammer path

- Ratio speed and the gap between hammer heads and the hammer path determine the final grain size.

Design

- Welded casing

- Side parts hydraulically swivellingh

- Big inspection doors

- Screwed lining with high-carbon steel plates

- Hammer path with wear-resistant baffle plates which are mechanically or hydraulically adjustable at all pivot points

- Dust-proof bearing of self-aligning rollers on the rotor shaft

- Rotor in disk-type design

- Resersible or single-direction design

- Hammer heads made of chrome alloy cast steel or composite casting

- Direct or V-belt drive

Advantage

- Coal and Potash industries

- Steel works

- Gypsum and limestone plants

To enable our experienced engineering staff to recommend the installation best suited to specific applications, answers to as many of the following questions as possible will result ina prompt and accurate solution to your screening requirements.

- Material to be screened

- Maximum feed dimension

- Approximate feed size analysis

- Moisture content

- Stickiness

- Bulk Density

- Separation sizes required

- Friability

- Abrasive Characteristics

- Do you intend close circuit operation

- Capacity desired in tons per hour

Looking for "Impact Hammer Crushers" ?

Explore More Products